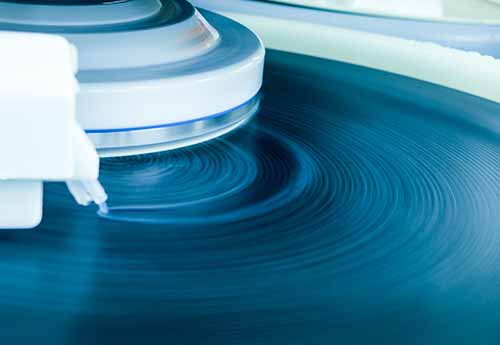

After a single crystal ingot rod is produced, it is cut into 1mm-thick wafers and polished. In traditional polishing applications, wafers are placed into a slurry of liquid with rotating pads. This process typically doesn’t exceed temperatures above 35°C (95°F) because if the wafers are overheated, they will be destroyed.

Because of this, temperature control is critical, and since the wafer is covered in a film of liquid, an 8-14 micron sensor is required in order to get an accurate temperature measurement – as the sensor can measure the temperature of the liquid coating the wafer.